25 degree bevel router bit 2 flute carbide tipped 3 flute tapered ball nose spiral router bit micrograin solid carbide up cut 45 degree bevel spiral router bit 2 flute carbide tipped.

Drop siding router bit.

A history of innovative manufacturing.

The 99 518 raised panel router bit is 2 1 2 inches long with a 1 2 inch shank an overall diameter of 3 1 2 inches and a large radius of 1 1 2 inches.

Here is the type of bit you d need.

You will want to slow your router way down when using large bits like that.

Wide and the other at 3 4 in.

Rabbeting bits cut a notch along the edge of a workpiece.

Starting at the left corner of the board slide the router bit up to the edge of the board until the pilot bearing is firmly against the board.

Freud cutting tools are backed by the freud limited lifetime cutting tool warranty to ensure customer satisfaction with every purchase.

To make the cove cut in the siding we used a 3 4 vertical raised panel router bit manufactured by freud.

A shaper would be a better tool if you are going to be making large quantities of siding.

Good catch that the tablesaw cove jig will only remove the height of the carbide or less per pass.

Flush trim bits trim the edge of one workpiece to match the edge of another.

I m afraid my router won t like to run the horizontal panel bit as the motor is only 2 1 4 hp bosch 1617evs.

So the first step in the milling process was to set up my router table with the raised panel bit using the leftover scrap piece as a guide.

This site will show the method that you can adapt.

A router could be used with a panel rising bit then cutting the rabbet on the table saw with a dado will be faster than using a router.

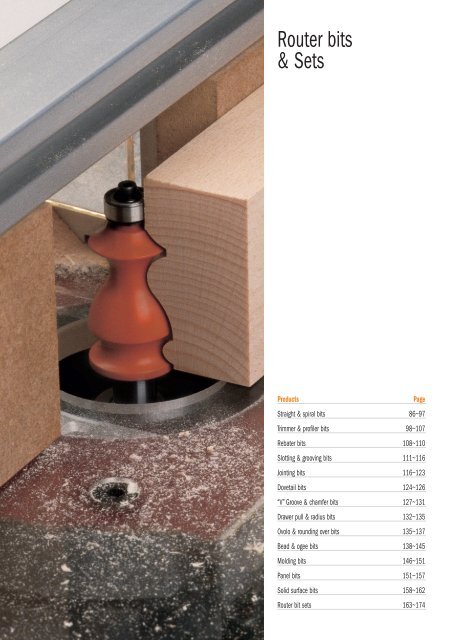

Common router bit profiles.

Straight bits make straight cuts such as dadoes and grooves.

To make a more traditional shiplap joint simply cut one rabbet at 1 2 in.

Round over bits soften the edge of a workpiece.

10 hold the router securely against the board and.

You can do that whole pattern on a table saw by using the curvature of the blade.

Chamfer bits cut a bevel on the edge of a workpiece.

I have not used a vertical panel bit 1 bit supposedly they need less hp because the diameter is not as large.

With the width the same on both sides of your board you can adjust the reveal between boards when you install the decorative shiplap siding.

Shaper cove cutters are closer to the sizes.